Returning Customer

I am a returning customer

Register Account

If you already have an account with us, please login at the login form.

Your Account Has Been Created!

Congratulations! Your new account has been successfully created!

You can now take advantage of member privileges to enhance your online shopping experience with us.

If you have ANY questions about the operation of this online shop, please e-mail the store owner.

A confirmation has been sent to the provided e-mail address. If you have not received it within the hour, please contact us.

Account Logout

You have been logged off your account. It is now safe to leave the computer.

Your shopping cart has been saved, the items inside it will be restored whenever you log back into your account.

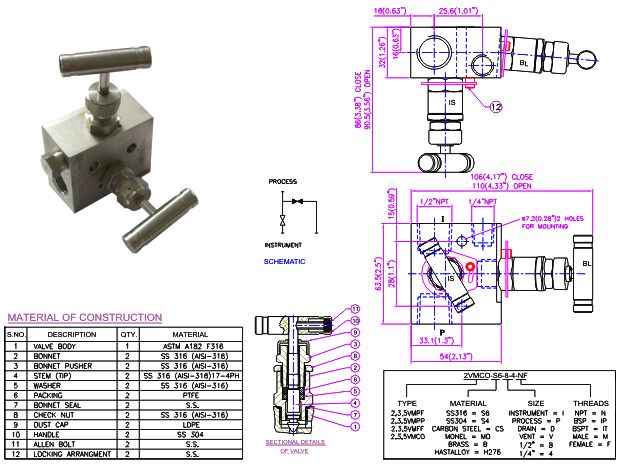

3 Valve pipe To Flange (Model No - 3VM-TT-FF) Tee Type

| Tubefit part no. | H | W | H1 | L | Size | CV | ORIFICE |

|---|---|---|---|---|---|---|---|

| 2VM-TTC-PF |

Features :

- 2 valve manifolds are designed for remote or separate mounting.

- Connecting from process side 1/2" npt(f) and instrument side 1/2" npt(f) connecting system impulse lines and transmitters, having simple two valves configuration which allows for easy block or isolate, bleed or vent valve callbration of a static pressure transmitter or gauge.

Bonnet Assembly :

- Bonnet : back seated blow out proof.

- Spindle : ground and thread rolled. Packing below thread.

- Spindle Tip : non-rotating tip shut-off type & soft seated.

- Dust cap : dust cap protects stem threads from external contamination heat code traceability

Technical specifications :

- Size : 1/4" & 1/2"

- End Connection : NPT, BSPT, BSP & Socket Weld.

- Working Pressure : 6000 psi (413 bar)

- Temperature Rating : PTFE 450° f(232°c) Grafoil 700° f (371°c)

- Material of Construction : SS 316l, SS 316, SS 304, C.S, F11,hastelloy,monel

- Optional sour gas service valves are available confirming to nace mr-01-75

- Stem Packing : PTFE, Grafoil.

- Orifice : ø4.7

- All valves are 100% factory tested prior to shipment.

Testing :

- Pneumatic seat test is performed at 1/4 of working pressure. Hydrostatic shell test is performed at 1.5 times the working pressure optional test are available upon request.

Lubrication :

- Molybdenum disulphide (mo s2)